Home > Semiconductor Tools > LED Tool

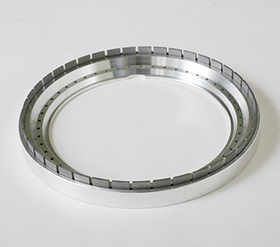

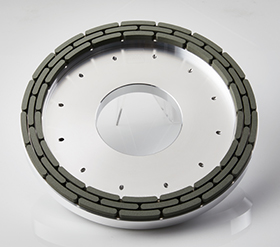

Sapphire LED Grinding Wheel

Usage

- Sapphire Ingot

- - Cup Wheel for the Sapphire Boule's C reference surface machining

- - Cup Wheel for Ingot C surface flat screen

- - Cup Wheel for cylindrical ingot grinder

- Sapphire Wafer

- -Back Grinder Wheel for Wafer Thinning Machining

Distinctive Features

- Quality First product design

- Improved process productivity and material life time

- - Optimize process customized to the machine & material

What is a Grinder Wheel befitting the LED process?

- Wheel design for minimizing grinding load

- - Minimize wafer damage by reducing contacting area between wheel's blades and wafer surface

- - Optimization of blade’s geometry and arrangement for easy grinding sludge ejection

- Quality-driven wheel design as well as lifetime

Processing material (Sapphire)

| Mineral Type | Hardness (Mohs) | Processing margin | Remarks |

|---|---|---|---|

| Diamond | 10 | - | Processing tool |

| SiC | 9.7 | 3% | SiC & Sapphire share the very similar hardness with the Diamond tools, which means it rarely leaves processing margin. Therefore, special wheels need to be designed. |

| Sapphire | 9.6 | 4% | |

| ~ | ~ | ~ | |

| Si | 6.2 | 38% | |

| Fe | 4.5 | 55% | |

| Zinc | 3.5 | 65% | |

| Gold | 2.5 | 75% | |

| Lead | 1.5 | 85% | |

| Graphite | 1 | 90% |